Every successful fire-sprinkler system begins with one principle: details always win. Choosing sch-10 or sch-40 may look like a simple specification step, but behind that choice sits decades of engineering logic influencing pressure ratings, thread performance, grooving behaviour, corrosion allowance, installation speed, and long-term reliability. When teams treat these details with care, they prevent rework, avoid hydraulic surprises, and build systems that stay dependable for decades. When they overlook them, even a well-designed system can become a maintenance liability. Understanding the differences between sch-10 and sch-40 is not just an engineering exercise—it is a foundation for sustainable fire protection.

Q1. What is the basic difference between sch-10 and sch-40 in fire-sprinkler systems?

Sch-10 and sch-40 refer to different pipe wall thicknesses.

- sch-10 → thinner wall

- sch-40 → thicker wall

Sch-40 has greater mechanical strength and supports deeper threads, while sch-10 is lighter, has a larger internal diameter, and reduces overall material weight. In fire-sprinkler work, sch-10 is used mostly in roll-grooved systems, while sch-40 is traditionally used in threaded systems.

Q2. How does wall thickness affect hydraulics and system performance?

Sch-10 provides a larger internal diameter, which reduces friction loss and improves flow in long runs. This often results in better hydraulic performance for commercial wet systems.

Sch-40’s thicker wall increases its pressure rating, making it suitable for high-pressure zones, pump discharges, industrial hazards, and areas with elevated mechanical stress. Both schedules meet NFPA-13 requirements when properly UL/ULC/FM listed.

Q3. How do sch-10 and sch-40 behave differently in threading versus grooving?

Threading removes steel from the pipe wall.

Because sch-40 starts thicker, it retains enough material to form strong, leak-resistant threads. This makes sch-40 the preferred choice for threaded branch lines, risers, pump rooms, and mechanical spaces.

Sch-10 grooves smoothly and requires less force during fabrication, which speeds installation and reduces labour hours. For this reason, sch-10 is the industry standard for grooved commercial systems.

Q4. How do weight, installation effort, and cost differ?

Sch-40 is significantly heavier, increasing handling difficulty and installation labour. It also requires stronger supports and adds to lifting fatigue.

Sch-10 is lighter, easier to handle, and faster to install, leading to lower total installed cost. Although sch-40 is more expensive due to its steel content and fabrication requirements, it remains the right choice for threaded and industrial environments.

Q5. Is there any difference in certification compatibility?

Both sch-10 and sch-40 can be:

- UL listed

- ULC listed

- FM approved

Certification—not wall thickness—is what determines NFPA-13 acceptance.

Typical listings include:

- sch-10 → often listed under A135 and A795

- sch-40 → often listed under A53 and A795

Inspectors focus on documentation accuracy, heat number traceability, and proper certification matches.

Q6. How do sch-10 and sch-40 apply differently in commercial vs industrial buildings?

Commercial buildings favour sch-10 for most grooved mains and branches due to speed, handling ease, and installation efficiency. Sch-40 is typically reserved for risers, fire pump rooms, and threaded components.

Industrial buildings require higher durability. Elevated pressures, vibration, temperature fluctuations, and physical impact often make sch-40 the default schedule across more of the system.

Q7. How should contractors choose between sch-10 and sch-40?

Choose sch-10 when:

- the system is roll-grooved

- faster installation matters

- overall project cost needs to be reduced

- handling weight is a factor

- the project is commercial or multi-residential

Choose sch-40 when:

- the pipe will be threaded

- mechanical rooms or risers need added strength

- pressure demands are higher

- the building is industrial

- the AHJ prefers conservative safety margins

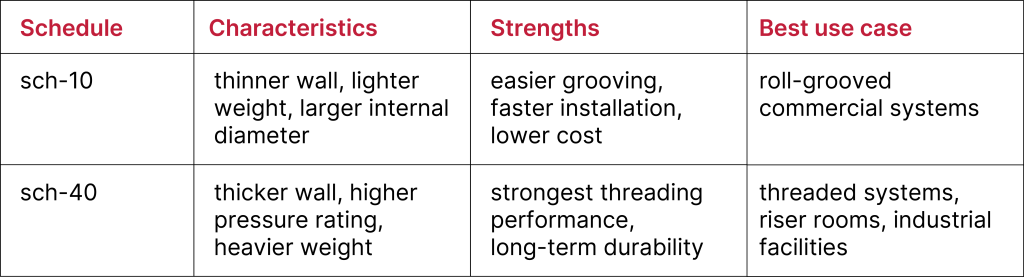

Comparison table: sch-10 vs sch-40