Q1. Why do North American markets rely on UL, ULC, and FM certifications?

UL, ULC, and FM are the primary independent certification bodies governing safety and performance in the fire-protection industry. Their standards ensure that fire-sprinkler pipe meets strict requirements for pressure performance, weld integrity, coating durability, dimensional tolerances, and long-term reliability. These certifications serve as the compliance foundation for NFPA 13, and AHJs require them before approving any fire-sprinkler installation.

Q2. What does UL Listed mean for fire-sprinkler pipe?

UL (Underwriters Laboratories) certifies fire-sprinkler pipe according to UL 852 and related standards. A product becomes UL Listed only after passing hydrostatic pressure testing, weld integrity verification (via X-ray or ultrasonic testing), dimensional conformance checks, coating evaluations, and long-term performance testing. UL also performs ongoing audits of manufacturing facilities to ensure consistency across production runs.

Q3. How is ULC different from UL?

ULC (Underwriters Laboratories of Canada) is the Canadian counterpart to UL and applies testing requirements aligned with Canadian building regulations and environmental conditions. ULC often requires additional corrosion-resistance evaluations and compliance with Canadian certification frameworks. In many Canadian jurisdictions, AHJs prefer or mandate ULC Listed pipe over UL Listed pipe.

Q4. What is FM Approved and why is it important?

FM Approvals, part of FM Global, certifies products based on risk prevention and loss-reduction criteria. FM testing includes evaluations for surge pressure, impact resistance, vibration tolerance, and performance in harsh industrial environments. FM Approved pipe is widely used in industrial facilities such as manufacturing plants, chemical storage areas, and high-hazard occupancies.

Q5. What types of testing do UL, ULC, and FM perform?

All three organizations conduct critical testing categories, including: – Hydrostatic testing for overpressure performance. – Weld integrity testing through X-ray, ultrasonic, or destructive sampling. – Coating durability evaluations for corrosion resistance. – Dimensional inspections for wall thickness and uniformity. – Cyclic testing to simulate long-term service conditions. These tests confirm that the pipe performs consistently across real-life fire-sprinkler applications.

Q6. What do AHJs look for when inspecting fire-sprinkler pipe?

AHJs typically check the certification marks on the pipe, including UL, ULC, or FM logos, the ASTM standard (A53, A135, or A795), the schedule (SCH-10 or SCH-40), heat numbers, and manufacturing markings. They also request documentation such as MTRs, listing sheets, and shipping records. AHJs verify that the selected pipe, joining method (threaded or grooved), and schedule match the listing requirements and NFPA 13 tables.

Q7. What are the risks of using non-certified or mismatched pipe?

Using non-certified or incorrectly labeled pipe exposes contractors and building owners to significant risks, including inspection failure, mandatory removal and replacement of the installed system, loss of insurance coverage, increased liability exposure, and potential system malfunction. Non-certified pipe is not permitted under NFPA 13 and is considered non-compliant by all AHJs.

Q8. How can contractors verify certification on received pipe bundles?

Verification should include:

- Inspecting printed markings for UL/ULC/FM logos, ASTM standards, schedules, and heat numbers.

- Matching heat numbers to the MTR provided by the mill.

- Reviewing UL/ULC/FM listing sheets for the specific product line.

- Checking bundle tags to confirm they correspond with the documentation.

- Ensuring the pipe schedule and joining method comply with the approved listing.

These steps help ensure the installed materials meet regulatory and project requirements.

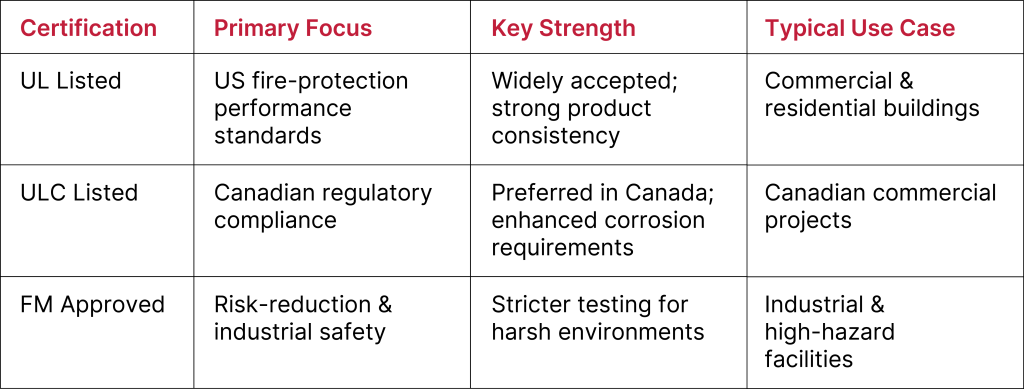

Summary Table: UL vs ULC vs FM